Inside Red Bull Powertrains: The four-year race to build an all-new F1 engine

Published: Jan 17, 2026

Hassan

Writer

Red Bull Racing will compete in Formula 1 with its own engines for the first time this season. But how did the project come together over the past four years, and what is its current status? Engine chief Ben Hodgkinson explains.

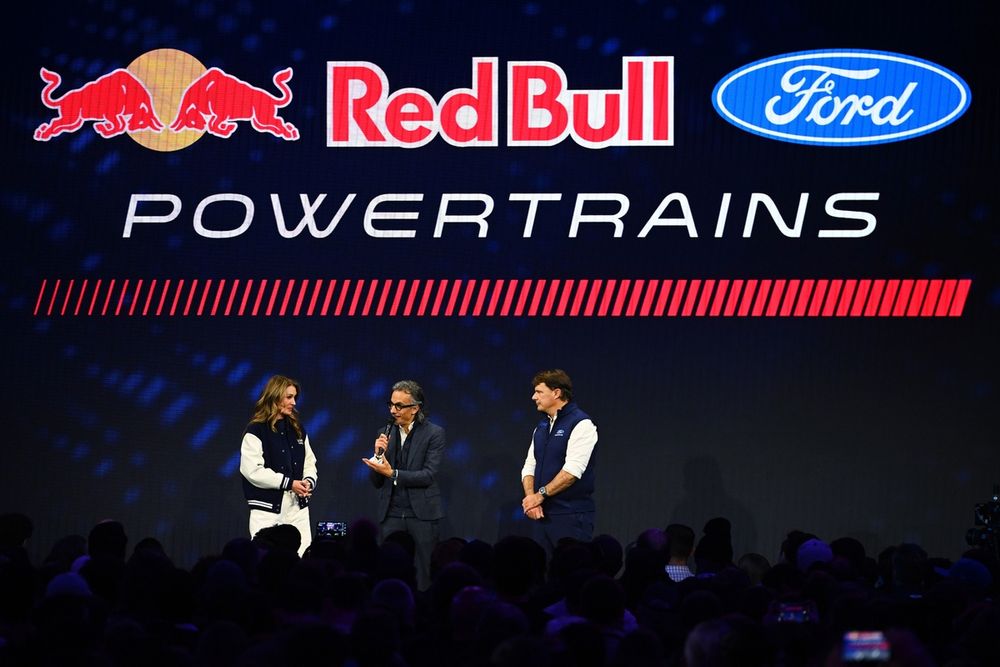

On Thursday, Red Bull and Ford officially launched their collaboration at an event in Detroit - Ford’s home city – though the ceremony was largely symbolic. Behind the scenes, work has been progressing for four years at Red Bull Campus in Milton Keynes.

Laurent Mekies described it as “insane” that an energy drink company would take on the challenge of building Formula 1 engines. Yet the idea had already been on Dietrich Mateschitz’s desk two decades ago.

“I can still remember that when I was at the team, I was encouraging them to buy Cosworth and build their own engines,” reflected David Coulthard on Red Bull’s F1 debut. “We were a customer to Ford first of all, then we were a customer to Ferrari, then Renault and being a customer sucks. I had experienced that at Renault and at McLaren-Mercedes, and it just felt we were always going to be handicapped by being a customer team.

“When the team bought Toro Rosso, I was like ‘hold on, it’s difficult enough to win with one team, how are we going to win with two teams?’ So, personally, this is something I was saying 20 years ago, we should have our own engines,” the Scot laughs.

“If you want to be in control of your own destiny, you don’t rely on anyone else. Now the team is 100% in control of its own destiny. It will be challenging, of course it will be, and it may not work in the beginning. It didn’t work in the beginning as a Formula 1 team, but it eventually worked, and Red Bull has the commitment, resources, and people to make it work in the long term.”

Coulthard’s perspective aligns with what Christian Horner – a key driver of the project – emphasised: bringing everything under one roof delivers long-term benefits, particularly when integrating the power unit with the chassis. After a frustrating split with Renault and Honda’s sudden departure from F1 at the end of 2021, Red Bull did not want to rely on another external partner.

However, establishing independence required far more than designing an engine under the 2026 regulations. Red Bull first had to build a dedicated facility in Milton Keynes and recruit skilled personnel. Work on the Jochen Rindt Building – the official engine hall – began in early 2022. The building sits across the road from MK7, and visitors enter via ‘Brodie’s Boulevard,’ named after Steve Brodie, a former Mercedes employee who joined in 2021 and played a key role in setting up the facility. In the corridor stands the V6 from the very first engine fire-up in August 2022, witnessed by Mateschitz shortly before his passing.

Red Bull also needed a partner for funding and expertise. Porsche was initially considered, but after talks fell through, Ford Performance director Mark Rushbrook simply emailed Horner: “Hey, Ford is interested. Would you like to talk?” Meetings with Bill Ford and Jim Farley soon followed, leading to an agreement.

By then, Ben Hodgkinson had already been planning the project for nearly a year. He was named director of Red Bull Powertrains in April 2021, moving from Mercedes High Performance Powertrains along with many others – Horner estimates around 220 people switched teams.

Almost five years later, Hodgkinson laughs: “Let's not beat around the bush, I probably got this job because of the success another team had!” he said, referencing Mercedes’ dominance since 2014.

“When I first got presented the opportunity, I loved the idea of it being a blank sheet of paper, not just the power unit but the whole company. We could custom build it to what we knew the regulations were going to be. It was a pretty cool opportunity, and I needed to try and turn that into an advantage.”

Starting from scratch, however, proved daunting. “Starting from scratch is a very short sentence but the gravity of what that meant took a while to really sink in. Trying to find what's turned into 700 people in a short space of time has been really challenging. The company started with just five people in a small office before the factories were even built,” Hodgkinson explained.

Staff were recruited rapidly from Red Bull, Honda, Mercedes, and other companies such as AVL. Hodgkinson described the experience as start-up like: “Every month, 20 more people started, so your roles and responsibilities changed from week to week. You had one person that was designing bits, ordering bits and building bits, and the next week another guy to build them turned up, so he stopped doing that. It's been a constantly evolving beast.”

Rushbrook added that integrating people from different corporate cultures presented another challenge. “Meanwhile, we've got to try and settle into what the Red Bull culture is, and we've got to try and extract everything from all the new starters to make sure that we are getting the best of all of those worlds. But actually, I think that has created a real cognitive diversity in the group, which I think has created some really high rate of change.

“The other thing that, if it was deliberate, it would be genius, but it was a bit of an accident: if you create a really bold and audacious project, it only really attracts bold and audacious people. All the people that are a bit cautious and think that sounds a bit risky, they stay put. The sort of people [that come in] fit the Red Bull culture like a glove, and it's brilliant for the rate of innovation. It's been an exciting but also intense four years.”

Technically, Red Bull began with the internal combustion engine, as the first fire-up in August 2022 demonstrated. The build shop was split between the V6 and a single cylinder, allowing new ideas to be tested more quickly and cheaply before scaling to the full engine – a method differing slightly from Honda’s, which initially focused more on electrical components.

The question of competitiveness remains, and Hodgkinson offers a fitting metaphor: “I've described it before to some of my teammates, it's like a 400-metre race. I use 400m because a 400m race is basically a sprint, so it feels like a sprint. But you're doing it in a stadium on your own, with no crowd, and in a different country to all of your competitors.”

“All I know is that we're running as fast as we possibly can,” he adds, noting the team has no insight into what competitors are doing.

Hodgkinson is confident in the foundations Red Bull Powertrains has laid. “Obviously I've got a lot of experience in designing F1 engines. I've been in it since the V10 days, so I know what a good company looks like. I've got the very unique opportunity here to try and shape what the perfect power unit manufacturer needed to look like. Red Bull has been very accommodating in terms of what facilities we've got, so I'm pretty confident in our facilities.

“I think the people we've got are amazing as well, so I think we've got all the ingredients. Whether it will turn into a Michelin meal, we'll have to see. I'm confident that we've built the right company and that we’ve got the right people, but I think confidence is something that somebody that's about to lose will have,” he laughs.

Even within Red Bull, there are no guarantees. Mekies described it as “naïve” to expect the team to immediately produce the best power unit. Hodgkinson, however, stresses that everything possible has been done over the past four years. It may not guarantee instant success, but it fulfills the long-held vision Dietrich Mateschitz had for the team.